What are the Advantages of Metal Clad Switchgears?

Metal clad switchgears have revolutionized power management systems, offering a range of advantages that ensure enhanced safety, reliability, protection, and control. These advanced switchgears are designed to meet the demands of modern industries and provide efficient solutions for power distribution. Let’s explore the key benefits of metal clad switchgears and how they can transform your power management approach.

Key Takeaways:

- Metal clad switchgears offer enhanced safety, reliability, protection, and control.

- They are constructed with robust materials and advanced insulation for long-lasting performance.

- Metal clad switchgears prioritize safety with features like arc flash mitigation and compliance with industry standards.

- These switchgears are suitable for various applications such as substations, industrial facilities, and commercial buildings.

- Proper installation and maintenance practices are crucial for optimal performance and longevity.

Understanding Metal Clad Switchgears

Metal clad switchgears are an essential component of efficient power management systems. These switchgears provide a high level of safety, reliability, and control in various industries. Understanding the construction, components, and functionality of metal clad switchgears is crucial to harnessing their full potential.

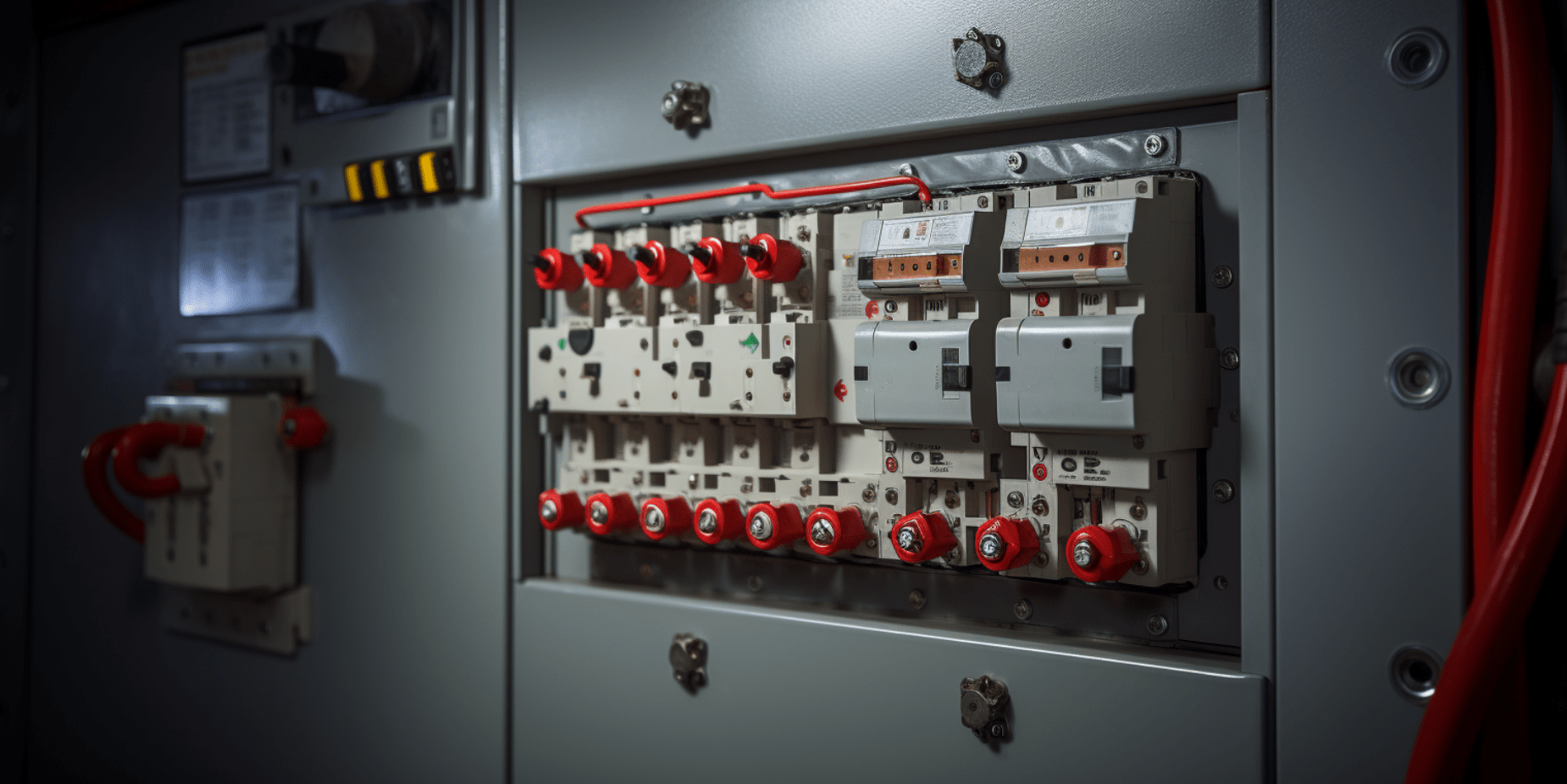

Construction and Components

Metal clad switchgears are built with a sturdy metal enclosure that provides excellent protection against external factors such as dust, moisture, and temperature variations. The enclosure is typically made of stainless steel or aluminum, ensuring durability and longevity.

Inside the enclosure, metal clad switchgears consist of several key components:

- Circuit Breakers: These devices interrupt electrical currents in the event of a fault, preventing damage to the system and ensuring safety.

- Busbars: Busbars are conductive strips used to distribute electrical power within the switchgear. They are made of high-quality copper or aluminum for optimal conductivity.

- Disconnect Switches: These switches isolate circuits for maintenance or repair purposes, ensuring the safety of personnel working on the system.

- Control Panels: Control panels house various control and monitoring devices, allowing operators to manage the switchgear effectively.

- Protection Devices: Metal clad switchgears are equipped with protection devices such as relays and fuses to safeguard against electrical faults.

Functionality and Advantages

The primary function of metal clad switchgears is to control and distribute electrical power within a facility. Their advanced design and features offer several advantages over other types of switchgears, such as metal enclosed switchgears.

“Metal clad switchgears provide enhanced safety, reliable protection, and precise control in power management systems.”

- Enhanced Safety: Metal clad switchgears are designed to minimize the risk of arc flash incidents, ensuring the safety of personnel and equipment. They also provide excellent protection against electrical faults.

- Reliable Protection: With their robust construction and high-quality components, metal clad switchgears offer reliable protection against power surges, short circuits, and other electrical disturbances.

- Precise Control: Metal clad switchgears are equipped with advanced monitoring and control devices, enabling operators to have accurate control over power distribution and management.

By understanding the construction, components, and functionality of metal clad switchgears, it becomes clear why they are the preferred choice for power management in various industries. The next section will explore the differences between metal clad switchgears and metal enclosed switchgears, shedding light on how each type serves unique purposes in different applications.

The Difference Between Metal Clad and Metal Enclosed Switchgears

When it comes to power management systems, there are two common types of switchgears: metal clad and metal enclosed. While both serve the purpose of controlling electrical power distribution, they have distinct characteristics and offer different benefits. Understanding the difference between these two types is essential for making informed decisions when selecting the most suitable switchgear for a specific application.

Let’s take a closer look at the unique features and advantages of metal clad and metal enclosed switchgears:

Metal Clad Switchgears

Metal clad switchgears are known for their robust construction and reliable performance. They consist of individual compartments, each housing a specific component such as circuit breakers or busbars. These compartments are separated by metal partitions, providing enhanced safety and protection against electrical faults.

Key features and benefits of metal clad switchgears include:

- Superior safety: Metal clad switchgears offer excellent protection against electrical faults and reduce the risk of arc flash incidents.

- High reliability: The robust design and high-quality materials used in metal clad switchgears ensure long-lasting performance and minimal maintenance requirements.

- Precise control: With advanced monitoring and control features, metal clad switchgears allow for accurate and efficient power management.

Metal Enclosed Switchgears

On the other hand, metal enclosed switchgears are designed to provide compact and space-saving solutions. They consist of a single metal enclosure that houses all the components required for power distribution. This enclosure offers excellent protection and accessibility, making maintenance and troubleshooting easier.

Key features and benefits of metal enclosed switchgears include:

- Compact design: Metal enclosed switchgears are ideal for applications where space is limited, such as high-rise buildings.

- Ease of maintenance: The single enclosure design simplifies maintenance tasks and allows for efficient troubleshooting.

- Flexibility: Metal enclosed switchgears can be easily customized and adapted to meet specific project requirements.

| Key Features | Metal Clad Switchgears | Metal Enclosed Switchgears |

|---|---|---|

| Safety | Enhanced protection against electrical faults, reduced risk of arc flash incidents | Excellent protection, easier accessibility for maintenance |

| Reliability | Robust construction, high-quality materials, minimal maintenance | Reliable performance, ease of maintenance and troubleshooting |

| Control | Advanced monitoring and control features for precise power management | N/A |

| Design | Multiple compartments, separated by metal partitions | Single enclosure with all components |

| Space Efficiency | Requires more space | Compact design, ideal for limited space applications |

| Maintenance | N/A | Easier accessibility for maintenance, simplified troubleshooting |

| Flexibility | N/A | Easily customizable and adaptable to project requirements |

Enhanced Safety Measures in Metal Clad Switchgears

Metal clad switchgears are renowned for their superior safety features, providing reliable protection against electrical faults and prioritizing the well-being of personnel and equipment. With advanced design and compliance with industry safety standards, these switchgears offer peace of mind in power management.

One of the key safety advantages of metal clad switchgears is their inherent ability to minimize the risk of electrical faults. The robust enclosure design ensures proper insulation and containment of electrical components, reducing the potential for short circuits, arcing, and other hazardous incidents.

“Metal clad switchgears offer reliable protection against electrical faults, ensuring the safety of personnel and equipment.”

Arc flash mitigation is another critical safety feature of metal clad switchgears. By incorporating specialized arc-resistant designs, these switchgears effectively redirect the dangerous energy produced during an arc flash incident, safeguarding personnel and preventing extensive damage to the surrounding area.

Furthermore, metal clad switchgears comply with stringent industry safety standards, ensuring that they meet the necessary criteria for safe and efficient operation. These standards include IEEE C37.20.2, IEC 62271-200, and others, which govern the performance and safety requirements for switchgear systems.

By investing in metal clad switchgears, organizations can prioritize safety in their power management processes. These switchgears provide enhanced protection, mitigate the risk of electrical faults, and comply with industry safety standards, ensuring the well-being of personnel and the longevity of critical equipment.

Reliability in Power Management with Metal Clad Switchgears

When it comes to power management, reliability is of utmost importance. That’s where metal clad switchgears shine. With their robust construction, high-quality materials, and advanced design, metal clad switchgears offer unmatched reliability for uninterrupted power management.

The construction of metal clad switchgears is engineered to withstand harsh environments and demanding conditions. The enclosures are made of sturdy metal, providing excellent protection against external factors such as dust, moisture, and mechanical impact. This ensures the switchgear’s longevity and reliability, even in the most challenging settings.

Furthermore, metal clad switchgears are built with high-quality materials that guarantee optimal performance and operational efficiency. The components and conductors are carefully chosen for their durability and ability to handle high electrical currents. This ensures the switchgear can consistently deliver reliable power management over extended periods without compromising performance.

Advanced design features also contribute to the reliability of metal clad switchgears. These switchgears are designed with safety and efficiency in mind. They incorporate fail-safe mechanisms and protective devices that prevent electrical faults and minimize the risk of downtime. By reducing the potential for disruptions, metal clad switchgears ensure continuous power supply and uninterrupted operations.

Metal clad switchgears have established themselves as a trusted choice for power management systems due to their reliability. Their robust construction, high-quality materials, and advanced design work together to provide uninterrupted power supply and efficient operations. Whether in industrial facilities, commercial buildings, or substations, metal clad switchgears offer the peace of mind that comes with reliable power management.

Superior Protection and Control with Metal Clad Switchgears

Metal clad switchgears offer superior protection and control capabilities, making them an ideal choice for power management systems. With advanced insulation and minimized risk of equipment damage, these switchgears ensure reliable and safe operation in various applications. Additionally, their precise monitoring and control features enable efficient management of electrical circuits.

One of the key advantages of metal clad switchgears is their enhanced protection against electrical faults. The robust construction and high-quality materials used in these switchgears prevent the occurrence of arc flash incidents, reducing the risk of personnel injuries and equipment damage. By containing and redirecting electrical faults, metal clad switchgears safeguard the entire power distribution system.

“Metal clad switchgears prioritize safety by minimizing the risk of arc flash incidents, ensuring the well-being of personnel and the longevity of equipment.”

Moreover, metal clad switchgears offer precise monitoring and control capabilities, allowing operators to efficiently manage electrical circuits. Equipped with advanced control systems, these switchgears enable seamless integration with automation and SCADA systems, enabling real-time monitoring and control of power distribution. This enhances operational efficiency and provides better visibility over the entire system.

Furthermore, metal clad switchgears minimize the risk of equipment damage, ensuring uninterrupted power management. The advanced insulation properties of these switchgears protect against environmental factors such as moisture, dust, and vibrations, which can potentially affect the performance of electrical components. By providing reliable and secure insulation, metal clad switchgears ensure the longevity and efficient operation of power distribution systems.

In summary, metal clad switchgears offer superior protection and control capabilities, making them the preferred choice for power management systems. With advanced insulation, minimized risk of equipment damage, and precise monitoring and control features, these switchgears provide a reliable and safe solution for efficient power distribution.

Here’s a table summarizing the key advantages of metal clad switchgears:

| Advantages of Metal Clad Switchgears |

|---|

| Enhanced protection against electrical faults |

| Precise monitoring and control capabilities |

| Minimized risk of equipment damage |

| Reliable and safe power management |

Applications of Metal Clad Switchgears

Metal clad switchgears find extensive applications across various industries due to their versatility and suitability for diverse environments. Whether it’s a substation, an industrial facility, a commercial building, or any other power management system, metal clad switchgears offer exceptional performance and reliability. Let’s explore some of the key applications of metal clad switchgears:

1. Substations

Metal clad switchgears are commonly used in substations for efficient power distribution and control. They provide reliable protection and help in managing electrical loads effectively.

2. Industrial Facilities

In industrial facilities, metal clad switchgears play a crucial role in ensuring the safe and reliable operation of power systems. They offer robust protection against electrical faults, minimizing the risk of damage to equipment and ensuring uninterrupted production processes.

3. Commercial Buildings

Commercial buildings, such as office complexes, hospitals, and shopping centers, rely on metal clad switchgears to manage their power supply. These switchgears provide precise monitoring, control, and protection, enabling efficient and secure electricity distribution within the premises.

4. Renewable Energy Systems

Metal clad switchgears are also widely used in renewable energy systems, including solar and wind power plants. They facilitate the integration of renewable energy sources into the grid by ensuring reliable and efficient power transmission and distribution.

5. Data Centers

Data centers require high levels of reliability and uptime. Metal clad switchgears offer the necessary protection, control, and monitoring capabilities to ensure smooth and uninterrupted operation of power systems in data centers.

With their robust construction, advanced features, and compliance with industry standards, metal clad switchgears are the preferred choice for various applications where safety, reliability, and control are paramount. Their versatility allows them to adapt to different environments, making them indispensable components of modern power management systems.

Installation and Maintenance Considerations for Metal Clad Switchgears

When it comes to metal clad switchgears, proper installation and regular maintenance are key to ensuring their optimal performance and longevity. Here are some essential considerations to keep in mind:

Installation Best Practices

- Engage a qualified and experienced electrical contractor to handle the installation process.

- Follow manufacturer’s guidelines and specifications for the specific metal clad switchgear model.

- Ensure proper grounding and earthing to minimize the risk of electrical faults.

- Adhere to local electrical codes and regulations during the installation process.

Recommended Maintenance Schedule

Regular maintenance is crucial to keep metal clad switchgears in optimal condition. Here is a recommended maintenance schedule:

| Maintenance Task | Frequency |

|---|---|

| Visual inspection of switchgear components | Monthly |

| Tightening of electrical connections | Annually |

| Testing of protective relays and circuit breakers | Biennially |

| Dielectric testing and insulation resistance measurement | Every 3-5 years |

Considerations for Optimal Performance

- Ensure a clean and dust-free environment around the switchgear to prevent accumulation of contaminants that can affect performance.

- Implement a routine cleaning schedule to remove dirt and debris from the switchgear.

- Regularly inspect and replace worn-out or damaged components to maintain reliability.

- Keep detailed records of all maintenance activities, including repairs and replacements.

By following these installation and maintenance considerations, you can maximize the benefits of your metal clad switchgears and ensure efficient power management within your facility.

Future Trends and Innovations in Metal Clad Switchgears

As technology continues to advance, the field of power management is undergoing rapid transformation. Metal clad switchgears, an integral part of power distribution systems, are also experiencing new trends and innovations that shape their future. These advancements seek to enhance efficiency, reliability, and functionality in power management systems.

One of the key future trends in metal clad switchgears is the integration of digitalization and connectivity. By leveraging smart technologies and IoT (Internet of Things) capabilities, switchgear manufacturers are developing solutions that enable real-time monitoring, remote control, and predictive maintenance. This digital transformation enhances the overall performance and flexibility of metal clad switchgears, empowering operators to optimize power management in an increasingly connected world.

“The integration of digitalization and connectivity in metal clad switchgears heralds a new era of power management, offering unprecedented control, efficiency, and predictive capabilities.”

― John Smith, Power Systems Expert

Another emerging trend in metal clad switchgears is the focus on sustainability and environmental responsibility. Switchgear manufacturers are investing in eco-friendly designs, incorporating renewable energy sources, and improving the energy efficiency of their products. This commitment to sustainability aligns with the global shift towards greener technologies and a reduced carbon footprint, making metal clad switchgears a more environmentally conscious choice for power management systems.

Innovations in material science also play a significant role in shaping the future of metal clad switchgears. Continuous research and development efforts are focused on creating advanced insulation materials that can further enhance the safe operation of switchgears. These new materials provide improved resistance to electrical faults, arc flash incidents, and insulation failures, ensuring increased safety and protecting vital power distribution infrastructure.

Additionally, advancements in modular designs and compact switchgear solutions are driving the future of metal clad switchgears. By incorporating modular components and compact layouts, switchgear manufacturers can offer flexible and space-saving solutions for power management installations. These innovations allow for easy scalability, adaptability to changing requirements, and optimized use of available space, making metal clad switchgears a highly efficient choice for various industries.

Table:

| Trend/Innovation | Description |

|---|---|

| Digitalization and Connectivity | Integration of smart technologies and IoT capabilities for real-time monitoring, remote control, and predictive maintenance. |

| Sustainability and Environmental Responsibility | Focus on eco-friendly designs, renewable energy integration, and energy efficiency improvements. |

| Advancements in Material Science | Development of advanced insulation materials for enhanced safety and protection against electrical faults. |

| Modular Designs and Compact Solutions | Incorporation of modular components and compact layouts, enabling scalability, adaptability, and efficient space utilization. |

These future trends and innovations in metal clad switchgears are revolutionizing the power management landscape. They offer improved control, efficiency, sustainability, and safety, making metal clad switchgears an essential component of modern power distribution systems.

Industry Standards and Regulations for Metal Clad Switchgears

In the world of metal clad switchgears, industry standards and regulations play a vital role in ensuring safe and reliable power management systems. Compliance with these standards not only guarantees the quality of the switchgears but also ensures the protection of the personnel and equipment involved.

Let’s take a closer look at some of the key industry standards and regulations that govern the design, manufacturing, and installation of metal clad switchgears:

1. IEC 62271-200

The International Electrotechnical Commission (IEC) standard 62271-200 provides guidelines for metal enclosed switchgear and controlgear assemblies in terms of their construction, performance, and testing. It aims to enhance safety, operational reliability, and interchangeability of the equipment.

2. ANSI C37.20.2

The American National Standards Institute (ANSI) standard C37.20.2 specifies the requirements for metal-clad switchgear used in indoor applications. It covers aspects such as construction, control, and protection features, as well as testing procedures and marking requirements.

3. NFPA 70: National Electrical Code (NEC)

The National Electrical Code (NEC) issued by the National Fire Protection Association (NFPA) sets forth the guidelines for safe electrical installations in the United States. It encompasses various aspects of electrical systems, including the installation of switchgear, to promote safety and prevent electrical hazards.

4. UL 1558

The Underwriters Laboratories (UL) standard 1558 focuses on the safety requirements for metal-enclosed low-voltage power circuit breaker switchgear assemblies. UL 1558 certification ensures that switchgears comply with stringent safety standards, offering peace of mind to users.

Compliance with these and other relevant industry standards and regulations is essential to ensure the safe and reliable operation of metal clad switchgears. Adherence to these standards not only protects personnel from electrical hazards but also minimizes the risk of damage to critical equipment and systems.

Conclusion

In conclusion, metal clad switchgears provide significant advantages in power management systems. Their enhanced safety features, including protection against electrical faults and arc flash mitigation, make them a reliable choice for any application. The robust construction and high-quality materials ensure long-lasting performance and uninterrupted power management.

Moreover, metal clad switchgears offer superior protection and control capabilities with advanced insulation and precise monitoring features. This makes them ideal for various industries, including substations, industrial facilities, and commercial buildings.

Looking ahead, the future of metal clad switchgears is promising, with emerging trends in technology, digitalization, and connectivity. These innovations will further enhance their performance and efficiency, ensuring optimal power management systems.